DC Fast Chargers vs. Regular EV Chargers: Key Differences and Best Charging Solutions

DC Fast Chargers vs. Regular EV Chargers: Key Differences and Best Charging Solutions

Dec 12, 2024

As we strive to achieve our climate goals, the transportation sector has undergone significant transformations. Public charging stations, including DC fast chargers and regular EV charging stations, play a critical role in the sustainable development of green transportation, whether for private passenger vehicles or commercial fleets. According to past statistics, the number of global electric vehicle charging points increased by 65% in 2023, and this growth trend continues.

Workersbee, a global leading EV charging plug solution provider, is dedicated to developing cutting-edge charging technologies to meet the personalized charging needs of customers. In this article, we will explore the differences between Direct Current (DC) high-power fast chargers and regular electric vehicle (EV) charging stations, and how Workersbee's innovative products can meet your business needs.

Regular EV charging stations refer to chargers that provide Alternating Current (AC) to electric vehicles, which is then converted to Direct Current (DC) by the vehicle's onboard charger. In North America, these are often referred to as Level 1 and Level 2 chargers, and they have a wide range of usage scenarios. Level 1 chargers use a standard 120V household outlet, providing very slow charging speeds. Level 2 chargers require a 240V power source, offering shorter charging times.

In workplaces, malls, and urban centers, Level 2 chargers are more common, providing faster and more cost-effective charging solutions.

Workersbee’s AC charging plugs are designed to be user-friendly, efficient, and reliable, compatible with over 99% of electric vehicles on the market, ensuring that EVs are always ready for use.

In the European market, the BYO chargers, which require drivers to carry an EV charging cable to connect to the chargers, are widely used. Workersbee's latest EV Charging Cable 2.3 is highly praised in Europe for its sleek appearance, dual protection features, and thoughtful design details.

DC fast charging stations feature high-power DC chargers that directly provide DC to the vehicle's battery, bypassing the onboard charger and requiring significantly less charging time. Popular examples include Tesla Superchargers, which can add 200 miles of range in just 15 minutes.

DC fast charging stations are typically located in large public charging areas and along highway corridors, making them ideal for EV drivers who need quick charging during long-distance travel.

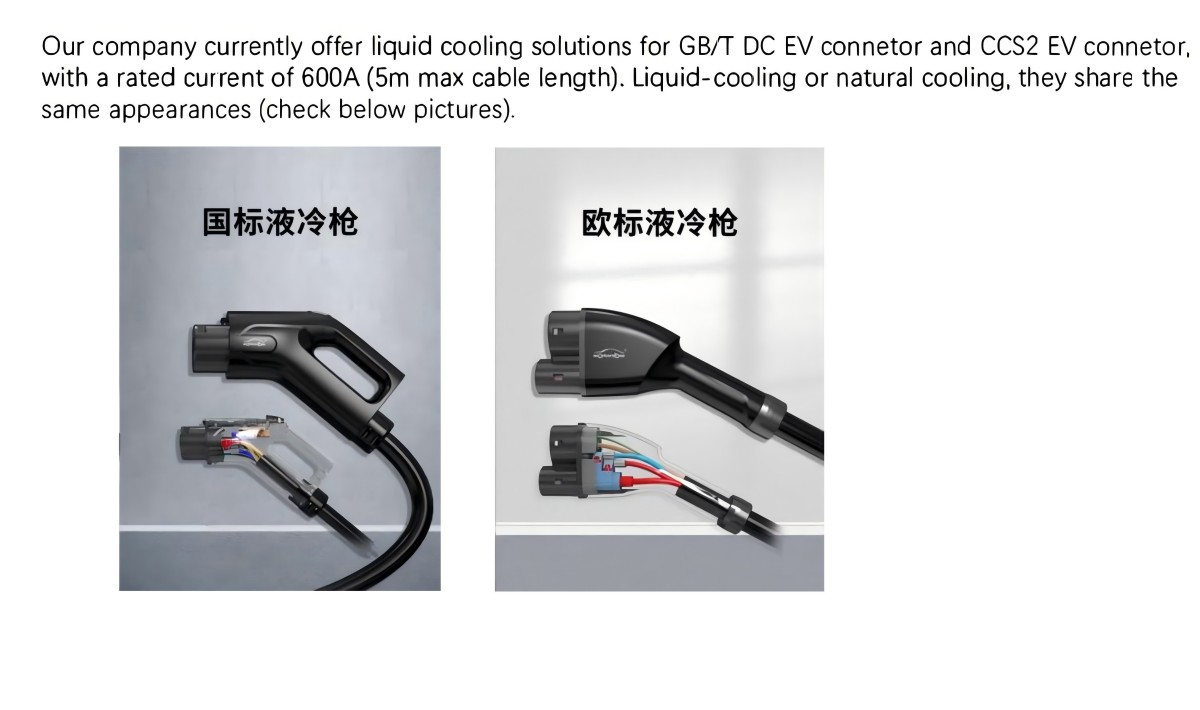

Workersbee’s high-power DC plugs boast robust natural or liquid cooling technologies, ensuring lightweight cables while continuously optimizing cable design and liquid cooling structures to achieve higher and more stable charging efficiency. These products undergo rigorous safety certifications and tests, ensuring reliability and service life.

Choosing Between Regular EV Charging Stations and DC Fast Charging Stations

1. Power Supply:

Regular EV charging stations use AC from the grid, which the vehicle’s onboard charger converts to DC for the battery.

DC fast chargers convert AC to high-power DC within the charger and directly provide it to the battery.

2. Charging Speed:

Level 1 chargers provide only 1.9 kW of power, making them suitable for overnight home charging due to their slow speed.

Level 2 chargers offer up to 19.2 kW of power, allowing for a full charge in a few hours.

DC fast chargers can typically charge an EV to 80% in just 30 minutes, with newer models being even faster.

3. Application Scenarios:

Residential Areas: Installing Level 2 chargers in apartments, streets, or private garages allows residents to charge overnight, ensuring full battery every morning.

Workplaces: Level 2 chargers are cost-effective for employees to charge during office hours, promoting the shift to electric vehicles.

Shopping Malls/Retail Stores: Mostly provide Level 2 chargers with a few DC fast chargers as a supplement, catering to both long-stay and quick-charge needs at the same time.

Highways: Primarily equipped with DC fast chargers for quick and convenient charging for long-distance travelers.

Commercial Fleets: Fleet operators install DC fast chargers at central hubs to keep fleets operational with minimal downtime.

4. Installation and Maintenance Costs

Financial Cost: DC fast chargers are more expensive due to higher power requirements and complex technology.

Installation Complexity: DC fast chargers require extensive power infrastructure and high site power requirements, often necessitating significant upgrades and advanced wiring.

Maintenance Costs: The cables and plugs used in regular and DC charging stations differ greatly. Replacing worn components in DC chargers is more costly, with higher daily maintenance costs.

Regulatory Approval: Low-power AC charging requires simple licensing, while DC fast charger installation needs specific approvals and regulatory permits, adding to the cost.

5.Charging Fees:

Due to lower installation and maintenance costs and lower power requirements, the charging fees for regular chargers are much less compared to the higher investment required for DC fast chargers.

Workersbee's Business Advantages

1. Over a decade of experience in EV charging plug research and production, with solid production capabilities, extensive experience, and professional teams.

2. Leading-edge technology driven by substantial R&D investment, continuously expanding product range, and improving user experience.

3. Commitment to high-quality products. Each batch has been rigorously tested and is very reliable in terms of performance, safety, protection, and experience.

4. Products certified by industry authorities, ensuring compliance with stringent safety and performance standards, such as CE, UKCA, UL, TUV, etc.

5. Customized charging solutions with comprehensive after-sales service to support smooth business operations.

Conclusion

Understanding the differences between regular EV charging stations and DC fast chargers is crucial for those looking to invest in the EV charging industry. While DC fast chargers require larger investments but offer faster charging speeds, regular chargers are less expensive and suitable for long-duration parking.

Workersbee is committed to providing high-quality, reliable chargers to meet the needs of individual drivers and commercial fleet operators.

We invite you to explore our extensive product offerings and unlock exclusive charging solutions to help your business STAY POWER.

Read More

DC Fast Chargers vs. Regular EV Chargers: Key Differences and Best Charging Solutions

DC Fast Chargers vs. Regular EV Chargers: Key Differences and Best Charging Solutions

Liquid-Cooled EV Charging Technology: Essential Advancements for High-Performance Charging Solutions

Liquid-Cooled EV Charging Technology: Essential Advancements for High-Performance Charging Solutions