Power Up: A Guide to Charging Speed of Different Types of Chargers

Power Up: A Guide to Charging Speed of Different Types of Chargers

Mar 21, 2024

The rapid development of electric vehicles is inseparable from the support of EVSE chargers. Charging an Electric car takes more than refilling a gas car from empty to full. Meanwhile, different types of chargers provide different charging speeds. The difference ranges from more than 20 minutes to dozens of hours. If more car owners encounter the latter, the popularity of electric vehicles will stall.

We need to understand the charging speeds of different types of chargers to ride the wave of electrified transportation.

What factors may affect charging speed

1. Charger types: They can be roughly divided into AC chargers, which charge relatively slowly, and DC chargers, which charge faster. AC is further divided into Level 1 and Level 2, which will be explained below.

2. Charger output power: A charger with greater output power will deliver more power to the car per unit time and charge faster.

3. EV battery capacity: It determines how much energy can be stored. Larger batteries will take longer to recharge.

4. State of Charge: The current SOC of the battery is closely related to the Charging Speed. In the range of 20%~80%, you will get better charging efficiency.

5. Vehicle charging capacity: The efficiency of the onboard charger (AC charging) and Battery Management Systems (DC charging) will also affect the charging speed, and the performance of each car is different. The car and the charger will have current and voltage limitations that need to be matched to transfer energy.

6. Temperature: Whether too cold or too hot can affect charging speed and battery performance. Cold may inhibit or prevent charging, while high temperatures may slow charging due to thermal management.

In addition to the above, factors such as battery aging, other electrical loads during charging, etc. can also affect the charging speed.

Types of Chargers

Level 1 Charger (AC)

The slowest but most convenient AC charger that plugs directly into a standard 120V household outlet for charging. The output power ranges from 1 to 1.92kW, charging approximately increases by 3-5 miles per hour, and it takes roughly dozens of hours to refill a BEV. It's frustrating, and perhaps why many consumers don't initially consider EVs. But it is suitable for car owners who have low commuting needs and can charge at home overnight.

Level 2 Charger (AC)

Provides up to 19.2kW power via 240V, greatly improves charging speed compared to Level 1 chargers. It is the favorite type of charger for EV owners when balancing many aspects (charging speed, charging cost, battery health, etc.).

It is often used for charging at homes, or in public places such as workplaces, shopping districts, or roadsides. Because drivers usually park in these places for a long time.

Typically, Level 2 chargers can add 10-50 miles of range per hour, making it easy to fully charge an electric vehicle in a few hours or overnight.

Aside from fixed wall box Level 2 chargers or EV Charging Stations offering Level 2 charging in residential areas or public spaces, many drivers are now opting for Portable Electric Vehicle Chargers. Not only can they provide Level 2 charging speeds, but they are also mobile and portable, making them convenient for drivers to recharge on trips.

The portable chargers of Workersbee, a long-established EVSE manufacturer, provide a variety of product models to choose from. They are lightweight, stylish, easy to operate, and have reliable charging and protection performance. The powerful control box provides diversified Smart Charging Solutions.

DC Fast Charging

The DC fast charger converts the AC power from the grid into DC power and directly delivers it to the battery for storage, making charging more efficient. It usually provides 25-400kW of power, which makes it possible to charge the battery to 80% in as quickly as 20 minutes. Different power levels also mean huge differences in charging time.

Because of high electrical requirements and high construction and maintenance costs, DC fast chargers are usually established along highway corridors and at public charging stations. It is more suitable for road trips and drivers who want to gain energy quickly.

The most popular High-Power Chargers today are none other than Tesla. Its Supercharger can add 200 miles of range to an electric vehicle in just 15 minutes. Powered by high reliability, high efficiency, and a comfortable charging experience, it dominates the North American charging market. Since Tesla opened the NACS charging standard at the end of 2022, EVSE manufacturers have actively poured into the NACS connector market.

Workersbee's R&D team quickly established a product project team last year to develop AC and DC plug products based on the NACS charging standard, which will be launched soon. We are deeply committed to Fast Charging Technology, further enriching our product models and expanding sales areas. With innovative, high-quality, and diversified R&D and production systems, we have built an outstanding DC fast-charging product matrix.

Wireless Charging

Wireless Charging uses electromagnetic induction to transmit electrical energy to the vehicle's battery without the cable connections. Charging speed depends on the Wireless EV Charging Pads's power and distance from the vehicle. Charging can be done while parked on the road or while driving, but the charging speed is not very high, the infrastructure requirements are very high and the investment is large.

Although it sounds very free and wonderful, there is still a long way to go before the goal of better serving electric vehicles.

Conclusion

AC Level 1 chargers can be powered by a regular household outlet and charge at 3-5 miles per hour. Suitable for charging at home or for low commuting requirements. Although it is the slowest charging solution, it does not require the additional cost of a charger installation.

AC Level 2 is more suitable for charging in long stops, typically at homes and workplaces. A full night or daytime work hours can make the car almost fully charged. Installation costs and charging fees are low, and sometimes can take advantage of time-of-use rates.

If there are higher charging needs and shorter charging time constraints, DCFC is a charging solution that will surprise drivers. They are often found on highways and urban public charging stations and are the fastest charging solution. The cost of building a site and charging is high, but it may only take 20 minutes to complete the charging task.

Market Insights

Although the charging speeds of AC and DC are vastly different. But for the health of vehicle batteries, we know that AC slow charging is better. Not to mention that charging speed also depends on the vehicle itself. Most PHEVs do not work with fast chargers.

Different charging methods have advantages and disadvantages and are suitable for different charging scenarios. Increasing charging speed significantly impacts car owners’ experience, which has far-reaching implications for the popularity of electric vehicles.

From the perspective of the charging market, we do not define a certain charger as always being the best choice. We can only say that it is more suitable for certain demand scenarios.

As a major player in the Electric Vehicle Charging market, charger and charging plug/cable manufacturers will also encounter some technical challenges during the research and development process when improving the charging speed of their products:

l In DCFC, limitations and risks caused by the temperature rise of connectors, plugs, and cables;

l High-frequency use of high-current fast charging may cause damage to battery health;

l The surge in electric vehicle charging demand brings excessive grid load, etc.

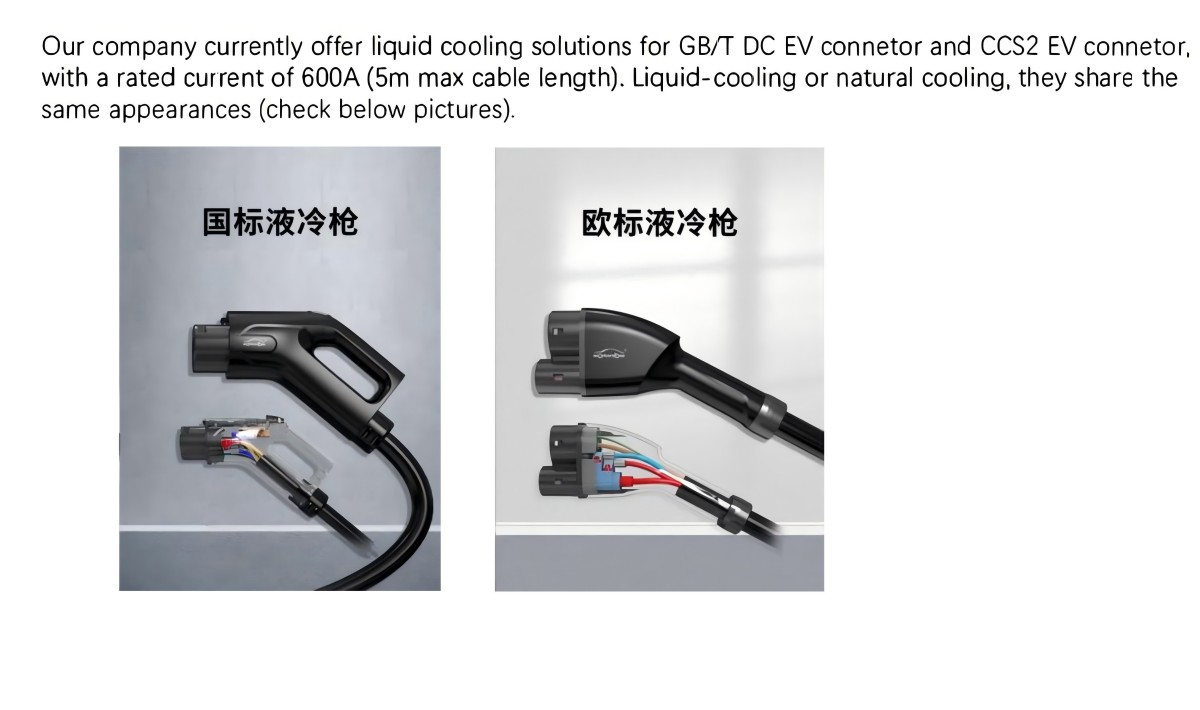

Workersbee has always paid attention to technological development and has made breakthrough innovations in multiple temperature control mechanisms, liquid cooling systems, and natural cooling technology. Solutions using new technologies have also gained attention and praise in the market. We are also working hard to find a better balance of charging speed and technology, as this is critical to both the owner's experience and the adoption of electric vehicles.

If your business requires solutions suitable for multiple charging scenarios, please discuss them with us to discover more possibilities. We welcome your curiosity and look forward to sharing and exploring more diversified technological possibilities.

Read More

Liquid-Cooled EV Charging Technology: Essential Advancements for High-Performance Charging Solutions

Liquid-Cooled EV Charging Technology: Essential Advancements for High-Performance Charging Solutions

Power Up: A Guide to Charging Speed of Different Types of Chargers

Power Up: A Guide to Charging Speed of Different Types of Chargers